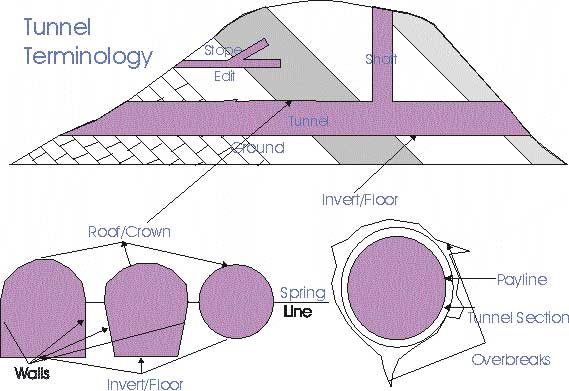

TUNNELS

Introduction

A tunnel is long,

narrow, and horizontal to sub horizontal essentially linear excavation that is

open to the ground surface at both ends. It is different from a cavern, which

is an underground opening whose length and width are nearly similar. Those two types of openings are end members

and every underground excavation is a combination to the two.

Related terms: A shaft is a

near vertical or vertical excavation that is open to the surface only at the

top whereas an edit or drift is similar to tunnel but open at

one end only. In practice a drift

precedes a tunnel. Stope or raise is an

inclined excavation driven from the main tunnel or drift in an upward

direction, generally for exploratory purposes.

Tunnel

Terminology

Overburden:

Any and all material overlying the tunnel is called overburden. It may be

consolidated or semi consolidated material.

Invert / Floor:

Is the bottommost portion of tunnel. In

railroad tunnels it is the surface on which the vehicles ply.

Roof/Crown/Back:

It is the upper portion of the tunnel above tunnel walls. The shape of the roof may be flat or curved

depending upon the tunnel, however, most of the tunnels have curved roof.

A SHAFT - LOOKING

VERTICALLY DOWNWARDS

Walls:

Both sides of a tunnel extending from floor to invert are called tunnel walls.

Spring line:

It is the line connecting all the points in a tunnel where the curved portion

of the roof intersects the top of the tunnel walls.

Ground:

Ground is the material through which the tunnel has to be driven and muck or

tailing is the material excavated

from the tunnel. Depending upon their

composition and structure the grounds are of the following type.

Few tunnels are excavated without the use of some kind of

artificial support. Terzaghi (1946) developed

a classification scheme to describe rocks and their load on steel

supports. Although this classification

scheme is fifty years old, and is limited with today's technology, the

classification scheme it is still quite useful for basic descriptions.

Intact rock: Intact rock contains neither joints nor hair cracks, and

thus breaks across sound rock. Spalling conditions, which is when thin slabs of

rock fall of the roof or walls of the tunnel, and popping conditions, where

rock slabs on the sides or roof of the tunnel spontaneously and violently

detach, may occur for several hours or days after blasting.

Stratified

rock: Stratified rock consists of individual strata

with little or no resistance against separation along strata boundaries.

Spalling conditions are quite common.

VARIOUS PARTS OF A TUNNEL

Moderately

jointed rock: Moderately jointed

rock contains joints and hair cracks, but blocks between the joints are locally

grown together or so intimately interlocked that vertical walls do not require

lateral support. Again, spalling and popping conditions may be encountered.

Blocky and

seamy rock: This consists of

chemically intact or nearly intact rock fragments, which are entirely separated

from each other and imperfectly interlocked.

The vertical walls of the tunnel may require support.

Crushed rock: Crushed rock is chemically intact, but extensively

fractured. If the crushed rock is fine grained and below the water table, it

will exhibit the properties of a water bearing sand.

Squeezing rock: Squeezing rock slowly advances into the tunnel without a

perceptible volume increase. This

condition requires a very high percentage of microscopic and submicroscopic

minerals or clay minerals with a low swelling capacity.

Swelling rock: Swelling rock advances into the tunnel primarily by the

expansion of the rock itself. This

condition seems to be limited to rocks containing clays, such as

montmorillonite, which have a high capacity to swell when hydrated.

Rock mass classification schemes abound, and nearly every

different author has different method of classifying rock masses for excavation

purposes. The following table 1

includes three more types in soft ground category.

Table: 1

|

Soft Ground |

Hard Ground |

|

Raveling Running Flowing Squeezing Swelling |

Firm

/ Intact Stratified Moderately

Jointed Blocky Seamy Crushed

/ Shattered |

Raveling: In reveling ground chunk or flakes of materials drop from

the exposed

Surface. This process may start soon after

excavation especially under water.

Running: Running ground is clear, loose gravel or coarse sound. Medium to

Fine sound may

also run if dry enough.

Flowing: Flowing ground is wet soil that moves like a viscous liquid

and tends to enter the tunnel through every gap in the lining.

Geological

Survey for a Tunnel

1. (a)

Geological profile along tunnel line and (b) Geological surface map including

soil, lithology, contacts, structure (fold, faults, joint etc) and water table

with water bearing structures.

2. Pitting,

drifting and/or drilling up to the invert or deeper in case of soft ground or

even drilling a pilot tunnel for long and large diameter tunnels.

3. Geophysical

Investigation including

a) The extent

of faulting and fracture of major magnitude.

b) Depth of

bedrock under deep soil cover.

c) Location of

particular rock formation and their possible intersections with the tunnel

invert.

4. Laboratory Tests

a) Microscopy

b) Structural

analysis

Geological Comments on a Tunnel

Design

1. Is the material (ground) hard/soft for

tunneling?

2. What part of tunnel needs support and

what type of supports is required.

3. Is

groundwater likely to be encountered, it so, in what proportion of the tunnel

and in what quantities.

4. Grouting

(Screen / Consolidation) is required or not.

Tunneling

Methods

Tunneling methods, as obvious depend upon the type of tunnel

and type of ground. Following are the

methods associated in the tunneling:

1. Full face method:

For small tunnels the whole tunnel section is blasted at once. However, in the longer tunnels if sufficient

bridging capacity is there, this method can be applied.

2. Heading & Benching Method: For grounds having shorter bridging capacity, the tunnel

is driven step by step. First heading

is done and then benching. We proceed

in this manner for whole length of the tunnel.

The length of head and bench to be blasted in one go is determined by

the bridging capacity (or standing time or stand up time) of the ground.

3. Side-drift method:

In relatively softer ground and where the tunnel diameter is rather large, this

method is useful. In this method

drifting from sides are done first. The

central portion is left for the time being which also acts as a support for

side-drifted tunnel. After erecting

required supports on the driven sides, the central portion is tunneled.

4. Multiple drift method:

For more softer ground and longer tunnels this method is very effective.

Instead of having only side drift we may have more drifts at first stage and

after giving required support to the excavated portion the remaining ground is

tunneled out.

5. Shield method:

In very soft ground (raveling, squeezing, running) this method is very

effective. The tunneling is done by an

automatic drill head, which keeps on providing instant support after each

excavation step.

The Excavation Cycle: The excavation cycle of a tunnel is as follows:

a) Drilling

b) Charging the

holes with explosives

c) Shooting /

blasting

d) Shortcreting

e) Ventilating

f) Erecting

supports and roof-bolting (where required)

g) Lining

(where required)

The Atlantic

Avenue Tunnel Notable

Vehicular Tunnels of the world

Tunnel Britannica tunnels of the world Longest Railroad Tunnels of the World

The

World's longest tunnel page - Railway Tunnels Tunnels Club Tunnel